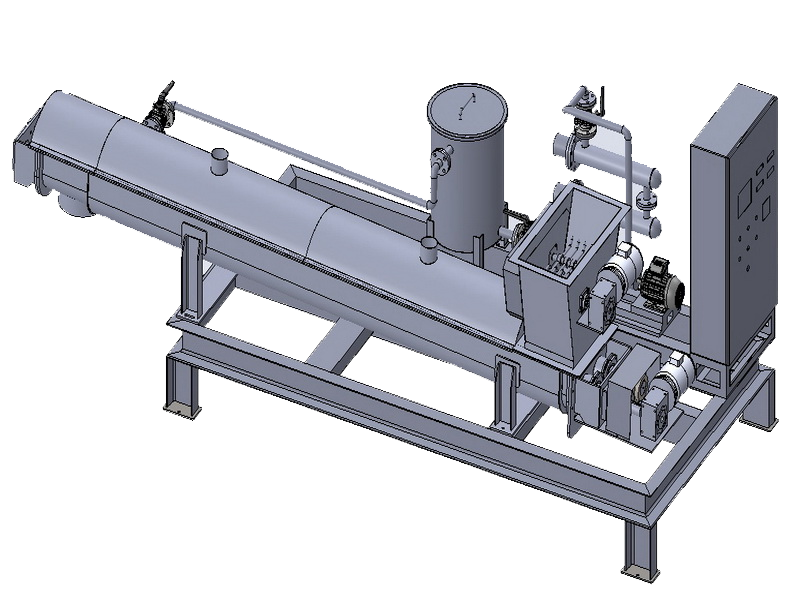

Screw Dryer

Description:

Screw conveyor is the use of dry heat kerosene mechanism to achieve the principle of water evaporation of heating the material in the water will evaporate.

Its drying process is carried out in the space of the conveyor, etc. added to the scrubber exhaust vapor extraction device may not cause air pollution and are reliable for large conveyors cake minced dried mud cake surface is not dried cake the aqueous filtrate which in the case of a high.

Product Features:

- Processing capacity: Screw conveyors for continuous operation dry, it can handle a large number of materials.

- Simple: to automate their own functioning.

- Maintenance is simple: because of simple structure, it is low maintenance costs.

- Scope: wide range of applications, operating speed can be set for the process to achieve the desired water content.

Description:

Screw conveyor is the use of dry heat kerosene mechanism to achieve the principle of water evaporation of heating the material in the water will evaporate.

Its drying process is carried out in the space of the conveyor, etc. added to the scrubber exhaust vapor extraction device may not cause air pollution and are reliable for large conveyors cake minced dried mud cake surface is not dried cake the aqueous filtrate which in the case of a high.

Product Features:

- Processing capacity: Screw conveyors for continuous operation dry, it can handle a large number of materials.

- Simple: to automate their own functioning.

- Maintenance is simple: because of simple structure, it is low maintenance costs.

- Scope: wide range of applications, operating speed can be set for the process to achieve the desired water content.

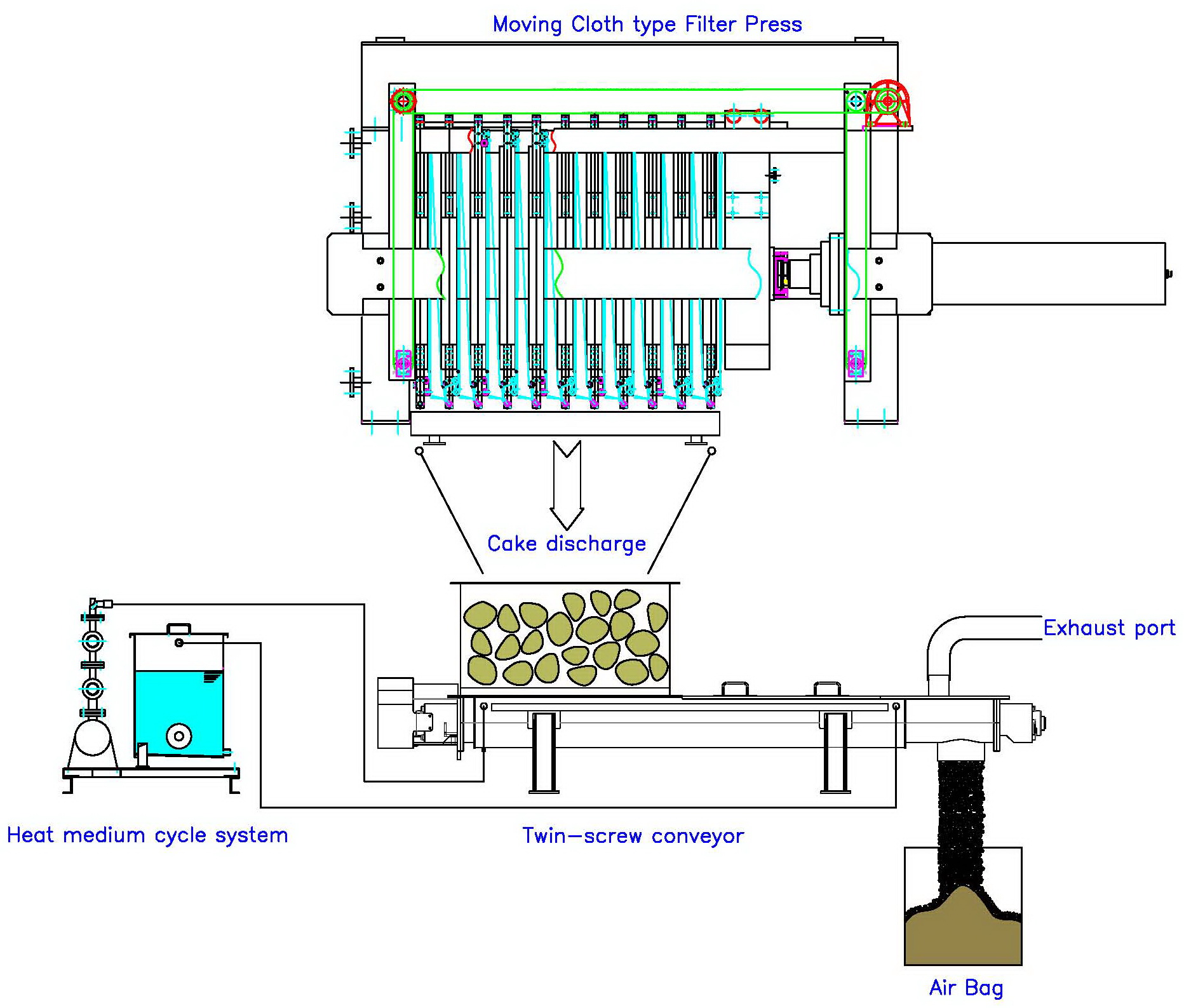

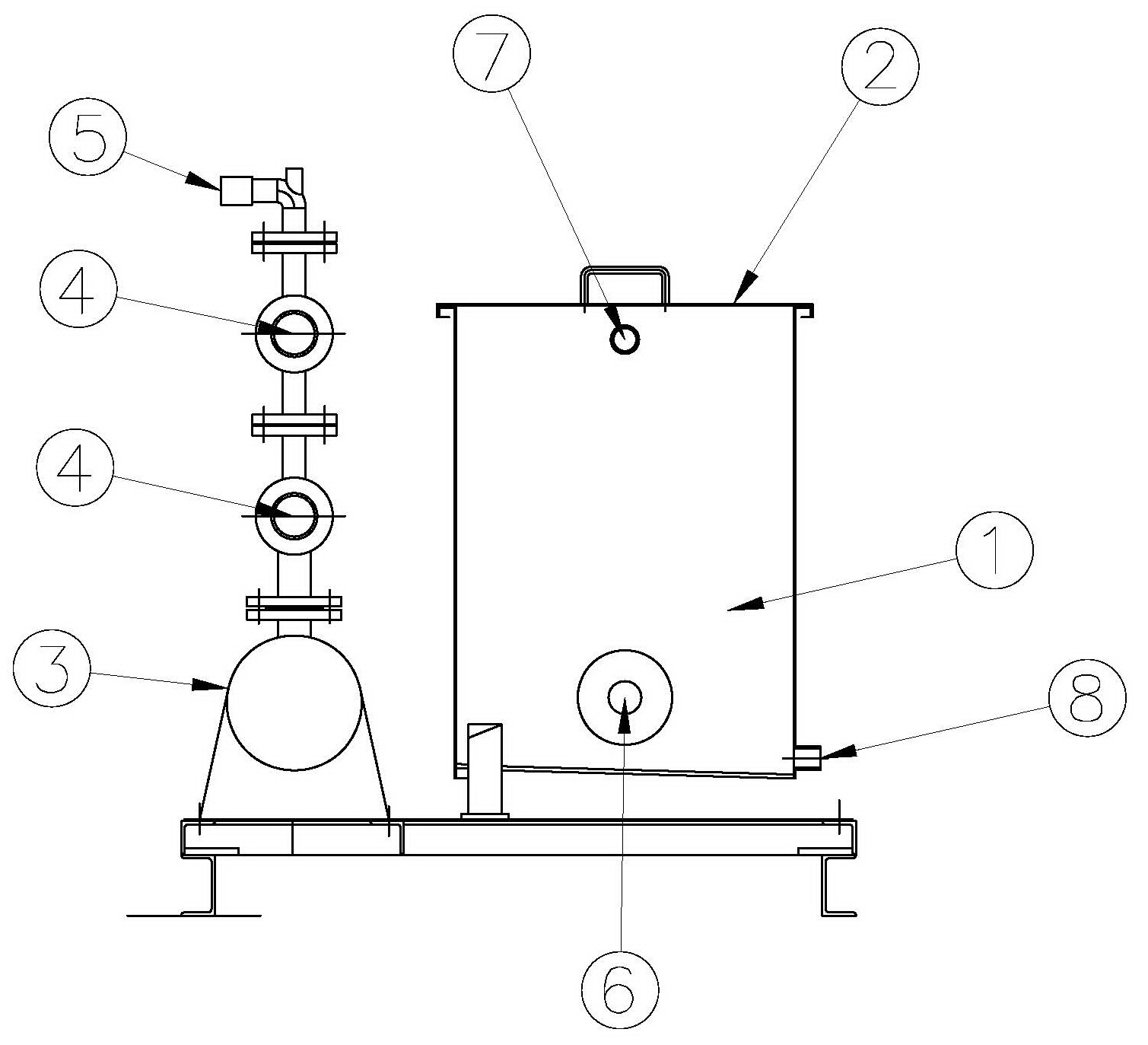

Flowchart:

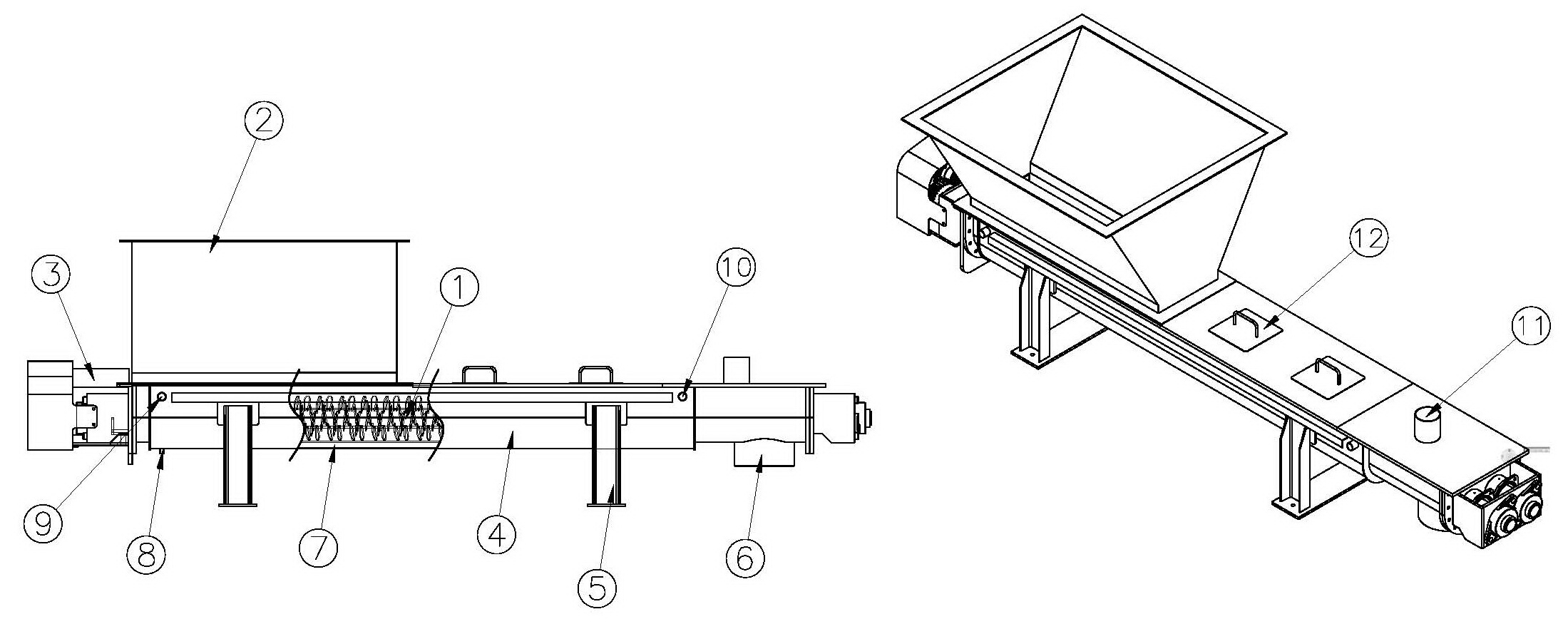

Dry screw conveyor structure description:

1. Screw gap 2.Hopper 3. Reducer motor 4. Heat medium Jacket 5. Foot 6. Discharge opening 7. Heat medium aisle 8. Heat medium mouth 9. Heat medium oil port into

1. Screw gap 2.Hopper 3. Reducer motor 4. Heat medium Jacket 5. Foot 6. Discharge opening 7. Heat medium aisle 8. Heat medium mouth 9. Heat medium oil port into

10. Heat medium oil port out 11. Exhaust port 12. Patrol mouth

Dry Screw conveyor mechanism made description:

1. Heat medium tank 2. Heat medium cover 3. Heat medium pump 4. Heater 5. Heat medium outlet (connect with conveyor) 6. Heat medium outlet (connect with pump) 7. Heat medium inlet 8. Heat medium mouth

1. Heat medium tank 2. Heat medium cover 3. Heat medium pump 4. Heater 5. Heat medium outlet (connect with conveyor) 6. Heat medium outlet (connect with pump) 7. Heat medium inlet 8. Heat medium mouth

| Model | Length(mm) | Width(mm) | Height(mm) | capacity(Liter/Hr) |

| SCCR200 | 3790 | 1100 | 1290 | 400 |

Note: Special specifications accepted